Why is cementing required

Cementing involves placing a cement-based slurry into a drill hole to seal fractures, cavities, or water-bearing zones. It is commonly required to control groundwater inflow, stop loss of circulation in broken ground, stabilize collapsing zones, and create a sealed hole for structural testing work. In practice, cementing is also used to restore drillability after severe fluid loss or when re-entering unstable ground requires a more competent hole wall.

What water or slurry loss is telling you

A sudden drop in returns usually indicates formation-related loss paths rather than a surface issue. Lost circulation commonly occurs when the bit intersects natural fissures, fractures, or caverns and fluid flows into newly available void space. In severe cases, loss can be partial, progressive, or catastrophic; the correct response depends on the risk to personnel, the economics of fluid, and the feasibility of sealing the zone.

When returns fall off, drilling can become unstable: torque and vibration often increase, cuttings transport can degrade, and gauge control becomes harder. Maintaining hole diameter and concentricity at this stage matters because irregular hole geometry can complicate both cement placement and casing advancement.

Grouting materials and lost circulation control

Modern cementing practice typically uses neat cement grout (sometimes modified for viscosity and bleed control) and, where needed, faster-setting systems for urgent sealing. When the main issue is loss through fractures or voids, operators often rely on lost circulation materials (LCMs)—additives introduced to help bridge and seal the loss zone. SLB’s glossary groups common LCMs into fibrous, flaky, and granular types (and explicitly lists plastic/cellophane sheeting as a typical flaky example).

Grouting solves the immediate problem, but good tool selection upstream can help. Well-matched drilling tools can help maintain stable cutting behavior and predictable gauge, which may reduce unplanned interventions related to unstable collars, irregular hole diameter, and loss-prone zones.【1】

High-pressure water control in underground drilling

In underground drilling, high-pressure water seams can discharge violently along the drill string and create serious safety risks. Typical control approaches include relief holes to bleed pressure, borehole plugs/valved sealing devices, and pressure cementing. Once sealed, drilling can often resume through the cemented zone; when cement placement is successful, core recovery can be restored and circulation stabilized.

The role of casing in drill hole stability

Casing isolates unstable ground, protects shallow formations, maintains a stable entry, and helps preserve circulation integrity. It is commonly required when collaring in broken or weathered ground, drilling through thick overburden, or when shallow zones are likely to cave and contaminate the hole.

Successful casing advancement depends heavily on the casing shoe. The shoe must cut efficiently in mixed ground, maintain alignment, and withstand abrasion and torque so the casing can be seated reliably—often through overburden until competent bedrock is reached. Epiroc notes that casing advancer systems are used to install casing through overburden to bedrock and can help protect the casing shoe from damage.

Reaming and stabilization during casing and re-entry

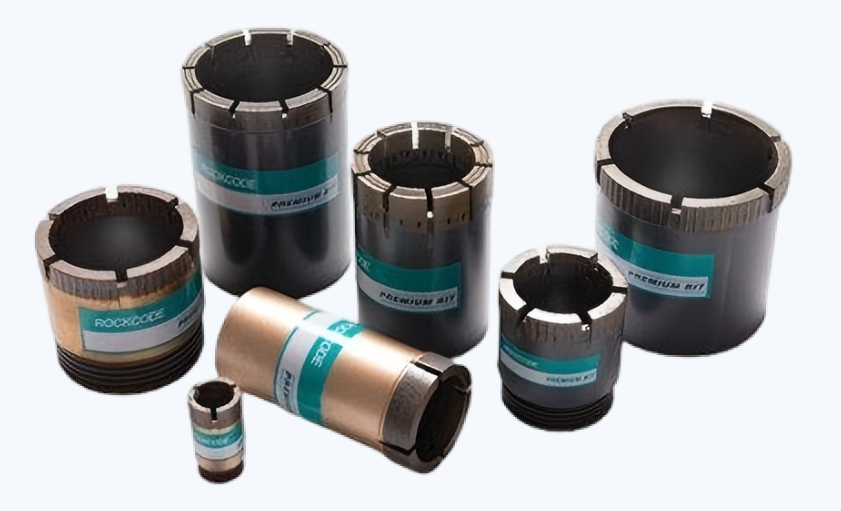

Casing refusal, deviation, and excessive wear are often driven by mismatched tooling rather than geology alone. A typical assembly uses a casing shoe sized to the formation, paired with reaming and stabilization components to maintain gauge and concentricity.

Reaming shells are widely described as an integral part of the diamond drilling system: they ream the hole to the proper size and stabilize the bottom of the drill string. Where deviation control and diameter control are concerns, stabilization practices often emphasize extending or optimizing reaming/stabilization to improve directional control and maintain hole diameter.

Why Choose ROCKCODE Reaming Shells and Stabilizers

• Premium Raw Materials: ROCKCODE sources tungsten powders, natural diamonds, and synthetic diamonds from global leaders. This ensures consistent quality and reliable performance from the very beginning stage. ROCKCODE's casing reamers shells/ stabilizers are manufactured with a hard, wear-resistant matrix that provides high resistance to erosion.

• Rich Manufacturing Experience: With over 10 years of production and extensive geological exploration data, ROCKCODE continuously refines its formulations and processes. Improved production efficiency allows ROCKCODE to provide high-quality casing reamers shells/ stabilizers with greater cost-effectiveness.

• Custom Design Capability: Our technical team can independently design and customize casing reamers shells/stabilizesr selection to meet specific geological formations and client requirements, delivering tailored drilling solutions.

• Technical Consultation: ROCKCODE is pleased to provide professional advice on casing reamers shells/stabilizers selection, application, and drilling optimization to help you improve efficiency and reduce operational costs.

→ For more information about ROCKCODE’s Products, please visit: https://www.rockcodebit.com/casing-rod-shoes.html 、https://www.rockcodebit.com/reaming-shell-stabilizer.html

→ Email us at: info@rockcodebit.com

→ Information in this article is for general reference only. For specific drilling projects and drilling bits, please consult qualified professionals. Thank you.

Source

【1】Cumming, J. D. (1956). Diamond drill handbook. (2nd ed.). Smit.

https://www.rockcodebit.com/cementing-and-casing-in-diamond-drilling.html